Molding Knives Direct

|

| Ordering Custom Knives |

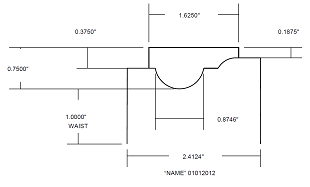

The first things to remember when designing a custom molding knife, are the old adages….”garbage in, garbage out,” and, “a picture is worth a thousand words.” Our knives and templates are created with top end CNC (Computer Numerical Control) equipment. What this means to you, is you will receive the highest quality, highest precision product possible. If you need to order another knife in that pattern again at some point in the future, We will have your program stored so you can be assured that it will be exactly like the first one you received. The information we receive from you is turned into a computer program that will drive the machines. The better and more information regarding what you require, the better product we can provide you, and in turn the higher your customer satisfaction. We are able to create your custom knife pattern from a number of different types of initial input, ranging from an actual wood sample of the pattern you are trying to duplicate, to a finished CAD file. The following is a list of methods for getting your design started: Order by stock # for standard patterns, for example WM 356, or WM 623. These stock numbers are to some degree, (there are exceptions) standard industry numbers. Send us a sample of your molding, the wood itself. Try to pick a piece that is in good shape with the pattern all there. Severe damage, weathering, cracks, or layers of paint will greatly diminish the ability to develop an accurate CAD file for your knife/template, and for us, the CAD file IS the program which will instruct our machines to cut your knife or template. Send us a tracing of the wood sample via us mail, FedX, or UPS. The same concerns remain as above, as far as the sample of the wood you are trying to match, however this method will require even more care from you. Here are a few helpful tips. 1. Download and print our, Knife Designers Guide and Worksheet. 2. Use a very sharp pencil, or a mechanical pencil with a very fine lead. A softer lead, such as #2 is best, because it allows a fine but dark out-line. DO NOT USE A BALLPOINT PEN, SHARPIE, or MAGIC MARKER! 3. Trace onto white paper or light yellow, legal pad type paper. Trace on a nice hard surface. Remember, your tracing will be scanned and input into a computer and used to actually program your knife/template. If the line is too light, the scanner will not be able to see it, so make sure there are no gaps. Tracing carefully once, without going over it again will give the best result. 4. Add some overall dimensions. This is less important when you send us your physical tracing, but if you are going to scan it yourself and e-mail it, or if you plan to FAX your tracing this becomes VERY important. ALL FAX MACHINES DISTORT THE ACTUALL SIZE OF YOUR TRACING! We will not accept faxes or e-mails without at LEAST an overall length denoted on the tracing. Be sure to note whether you are showing us the wood or the knife side of the drawing. They are mirror images of each other. High Tech Note This, in theory anyway, is an ideal way to have your knife created. There are huge advantages to this method, but it is not without its problems. The CAD file, as e-mailed to us, in either DXF or DWG format, must be created to correct scale. It must be done in such a manner as to insure your output is compatible with our equipment. They must be output in such a matter as to insure that there are no gaps or overlaps. Another common problem is for radius’s and arcs to become faceted and become comprised of hundreds of short lines. Many people are fully capable of working in CAD programs, but that does not insure a useable CAD file output for use in machine tool programming. Another concern is again; add a few dimensions so there is no question of scale. You don’t need to go overboard, in fact but just the overall width will usually suffice. Again, make sure we know whether you have drawn the wood or the knife. There are definite proto-calls for creating knives to fit different types of machines. It may be easier for you to “draw the wood,” and let us create your knife around it. We can, however, help you with any questions regarding knife design.

|